手 機:18803265188

電 話:0316-2318558

傳 真:0316-2360318

郵 箱:thch1658@126.com

手 機:18803265188

電 話:0316-2318558

傳 真:0316-2360318

郵 箱:thch1658@126.com

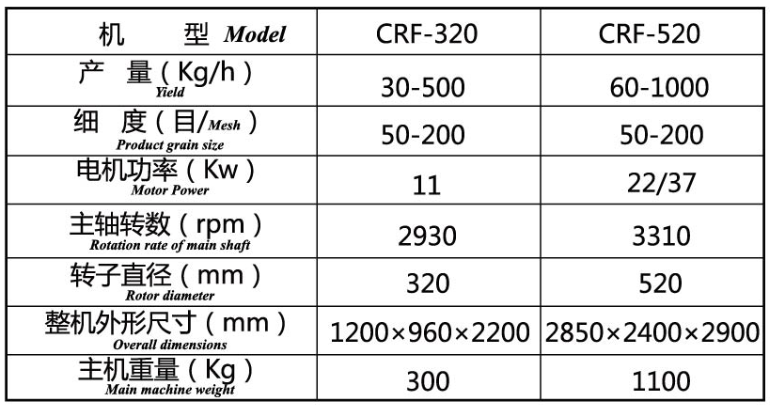

CRF系列粉粹機組是消化接收了國際進步前輩手藝,連系現實環境研制勝利的渦流式破壞機。該機具備微粒小,溫升小等特色。機組由破壞主機、微粉搜集器、布袋搜集器、保送管道、電氣節制柜及離心風機構成。物料在主機外部逗留時候短,可避免過分破壞及-陛能不變,樂音低,耗電省、出產率高、外型雅觀等特色。是實拍、醫藥、化工、涂料、農藥等行業抱負的微細破壞裝備。

任務道理

本機接納了渦流的高速扭轉活動,在破壞室內發生了壯大的氣流。物料在負壓下由進料口被吸入破壞室,在葉片與模塊間壯大的氣流感化下,發生打擊、剪切和研磨,由氣流將破壞室的熱量帶走,是破壞進程中發生的熱量不會急劇升溫。制品物料從篩網流出,進步出產率,破壞細度可由篩網的目數自行調理,制品細度平均不變。

CRF series splintered unit is absorbing the international advanced technology, combined with the actual situation in the successful development of the vortex mill. The machine has a small particulates, temperature and other characteristics. Crushed by the host unit, powder collector, bag collectors, pipelines, electrical control cabinet and centrifugal fan components. Material in the short residence time inside the host, to prevent excessive crushing and - Pi stable, low noise, low power consumption, high productivity, handsome in appearance and other characteristics. Is ideal for real shot, pharmaceutical, chemical, paint, pesticides and other industries fine grinding equipment.

Works

The machine uses a high-speed rotating vortex motion in the grinding room had a strong airflow. Material in the negative pressure is sucked into the feed opening crushing chamber between the blade and the module in the powerful airflow, an impact, shearing and grinding, the grinding chamber by a stream of the heat away, the heat generated during the grinding not rapid warming. Finished material flowing from the screen, increase productivity, grinding fineness mesh sieve by self-regulation, product fineness uniform and stable.